3 Questions to Find the Balance of a Seasonal Product Cycle

Feb 3, 2019

Manufacturing and distribution companies that handle seasonal merchandise know that correctly managing supply and demand can be the difference between having a warehouse with minimal inventory (which is ideal) and carrying the burden of leftover inventory (the result of poor planning) after peak season. Accurately forecasting the demand for seasonal merchandise is difficult because of the many variables involved. Companies can, however, plan their seasonal inventories more effectively by studying historical sales data, forecasting future demand, and analyzing the sensitivity needed for unexpected events.

What Products Has Your Company Sold in the Past?

The first step is to create systematic reporting that will allow you to carefully study historical sales patterns—focusing on products that show marked fluctuations in sales. Keep in mind that "seasonal" can have multiple definitions related to product distribution, including annual holidays or events (e.g., back-to-school). Additionally, some items span multiple seasonal periods. For instance, the seasonal period for cold weather gear may span fall through winter. And sporting equipment—such as basketballs and footballs—may sell during all four seasons, but sales typically peak during that sport’s professional season. Keeping detailed sales records helps identify patterns and track return on investment over time. These data then determine what types of seasonal inventory are smart investments.

What (and How Much) of Your Products Will Sell in the Future?

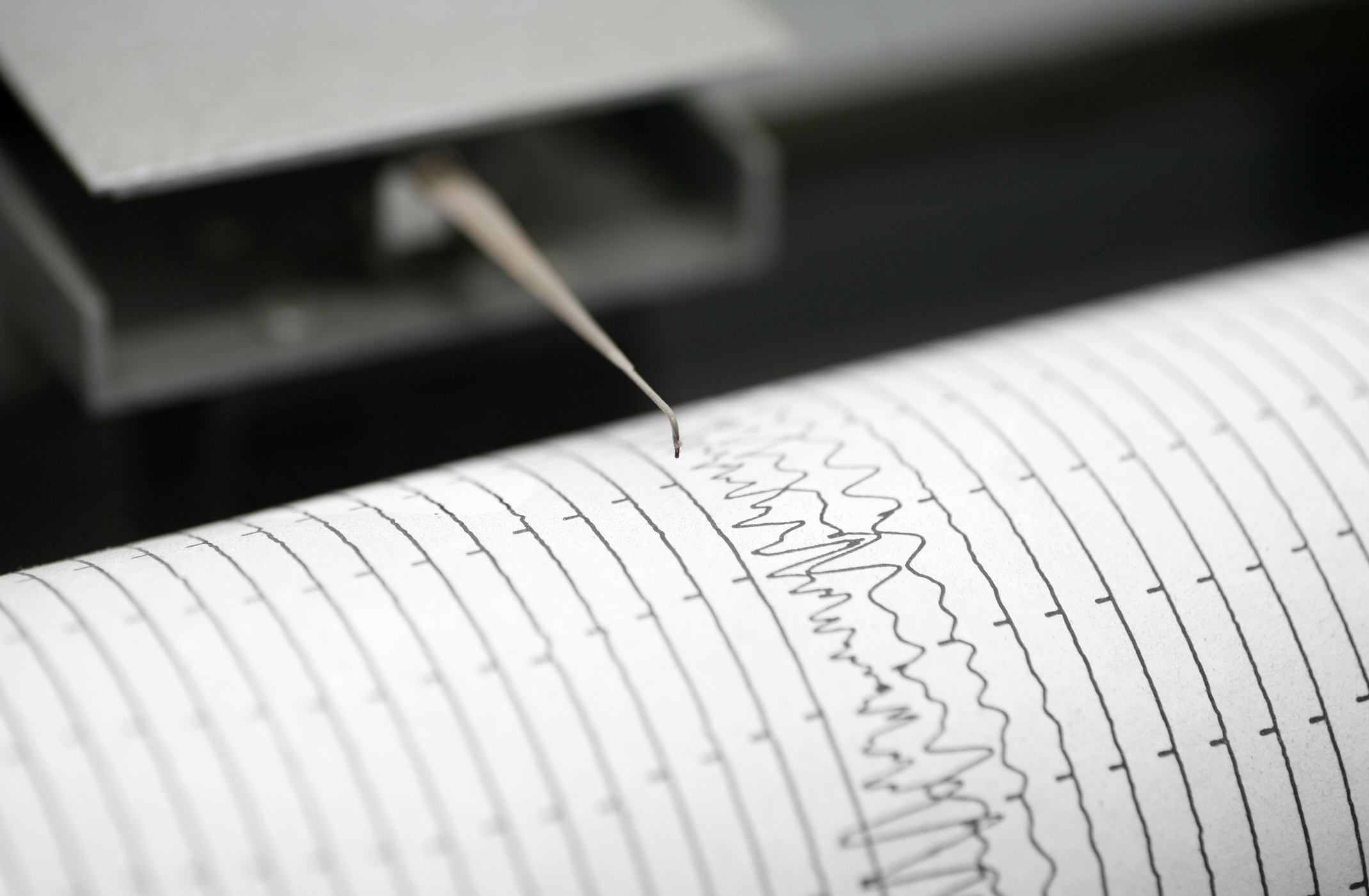

It is best to forecast demand for non-seasonal products (i.e., those with consistent usage and sales) by taking a rolling average of sales during the past six months and placing more emphasis on the most recent. In contrast, seasonal product forecasting requires taking a future rolling average, which involves comparing a future period to the same period from the prior year, with more emphasis on the month being forecasted.

So if you're trying to forecast sales demand for summer items in June, you could apply an average from May through July of the prior sales year, placing more emphasis on the month of June. But because the sales data will be a year old, it may not reflect other variables that can affect the demand for seasonal products in the current year. Therefore, you'll also need to consider overall trends in the growth or decline of your company's sales, changing market conditions, competitor activity, and any adverse events.

In any case, it's better for a company’s bottom line if it sells out all of its seasonal items instead of warehousing the surplus stock until next year. Running out too early may benefit competitors and may not be a viable option for a company's customers dependent on a sole source for their supply. Demand forecasting and inventory planning software help automate and simplify the forecasting process.

What's the "X Factor" of Unplanned Circumstances?

By combining an understanding of historical sales patterns with the use of future rolling average forecasting and an automated software package, a company can significantly improve how it manages its seasonal inventory. But because unplanned occurrences are inevitable in a dynamic marketplace, a perfect product demand forecast is next to impossible. For example, sales can be suddenly impacted by an economic slowdown or atypical seasonal weather. So what can you do to reduce or eliminate seasonal leftovers? Two viable solutions include dropping prices or making charitable contributions.

1. Mark it down sooner rather than later. Applying smaller markdowns while sales levels are still high can help entice customers to buy more, thereby lessening the amount of leftover inventory and improving profitability. If you wait until the end of the season, then you may have to apply bigger discounts to move items, cutting deeply into your profitability.

2. Give excess inventory to charity. A company may qualify for a tax deduction on seasonal inventory donated to a qualified charity. The available deduction varies depending on the structure of the business and the type of inventory donated. CRI’s tax advisors can help you properly determine the applicable deduction.

Finding a Balance with Seasonal Merchandise

When handling seasonal merchandise, it can be the best of times (when demand is high) or the worst of times (when your warehouse shelves are full of products no one wants). Successfully planning a seasonal product cycle is no easy feat, but with some extra legwork, you can reduce the variables and reap more of the benefits. Contact your local CRI professional for help with your unique situation.